Views: 0 Author: Site Editor Publish Time: 2026-02-05 Origin: Site

You play a key role in the fast-growing world of foundation cream manufacturing. The market continues to expand:

The global foundation cream market reached $9.5 billion in 2023.

Projections show growth to $14.8 billion by 2032, with a CAGR of 4.9%.

The cosmetics foundation sector expects a 6.38% annual growth rate through 2032.

Vacuum emulsifiers integrate heating, mixing, high-shear homogenization, and deaeration in a single vessel, producing a uniform, bubble-free semisolid in one pass.

When you use advanced equipment from Jaywin Machinery, you ensure consistent product quality and efficient production at every stage.

Foundation cream manufacturing is a growing market, projected to reach $14.8 billion by 2032. Understanding market trends can help you capitalize on opportunities.

Use high-quality ingredients like emollients, water, and emulsifiers to create a smooth, long-lasting foundation cream. Each component plays a crucial role in texture and performance.

Precise measurement and monitoring of parameters like pH and viscosity are essential for maintaining product quality. Regular testing helps ensure safety and consistency.

Invest in advanced equipment from Jaywin Machinery to enhance production efficiency and product quality. Reliable machines reduce contamination risks and improve results.

Automate your filling and packaging processes to increase efficiency and maintain hygiene standards. Automation can significantly reduce labor costs and improve accuracy.

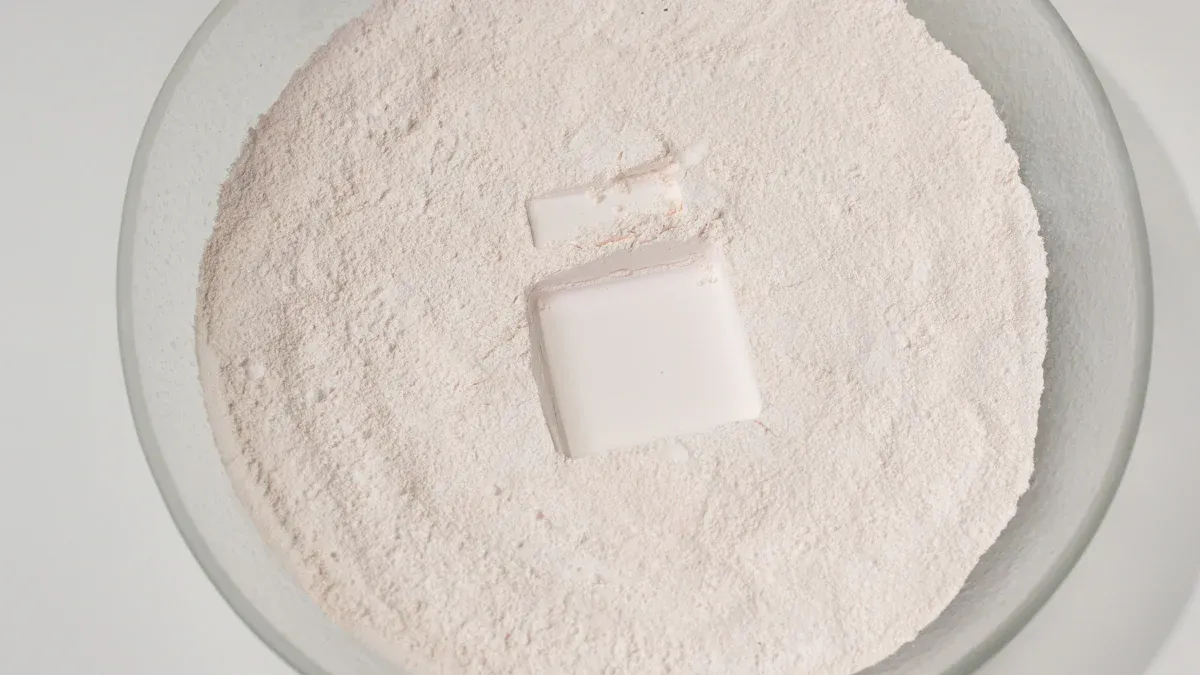

Image Source: pexels

A high-quality foundation cream starts with the right blend of ingredients. You need to understand each component’s role to create a product that feels smooth, looks natural, and lasts all day.

Emollients and oils give foundation cream its signature texture and moisturizing effect. You often see ingredients like mineral oil, squalane, or plant-based oils. These help your skin feel soft and prevent dryness. Emollients also help the cream glide easily during application, making blending effortless.

Emollients lock in moisture.

Oils add richness and improve spreadability.

Both contribute to a smooth, even finish.

Water phase components form the backbone of most foundation creams. You usually find purified water, hydrosols, or botanical extracts in this phase. The water phase hydrates your skin and helps dissolve other ingredients.

The water phase often makes up 70% or more of the total formula.

Many recipes use 60-80% distilled water.

Water ensures a lightweight, comfortable feel.

Tip: A higher water content can make your foundation feel fresher and less greasy.

You need emulsifiers and stabilizers to keep oil and water mixed together. Without them, your foundation would separate. Using a blend of emulsifiers improves stability.

Type of Emulsifier | Characteristics | Examples |

|---|---|---|

Cationic | Positive charge | Behentrimonium methosulfate |

Non-ionic | Versatile, stable | Polysorbate 60, Polysorbate 80 |

Polymeric | Forms gel networks | Sepigel 305, Simulgel, Cosmedia ACE |

Add thickeners like xanthan gum (about 0.3%) and cetearyl alcohol (2% or more) to boost stability.

Pigments give foundation its color and coverage. You can choose from a variety of pigment types to match different skin tones and achieve the desired effect.

Type of Pigment | Description |

|---|---|

Traditional Pigments | Iron oxides, titanium dioxide—provide base color and opacity. |

Effect Pigments | Add shimmer or special effects for a unique finish. |

Inorganic Pigments | Duller but more stable to heat and light, ensuring durability. |

Iron Oxides | Black, yellow, red—blend for custom shades. |

White Pigments | Titanium dioxide, zinc oxide—offer strong coverage and stability. |

Pigments enhance color and coverage.

Proper selection ensures long-lasting wear and a natural look.

You start every foundation cream manufacturing batch by weighing and measuring ingredients with precision. This step sets the stage for consistent results. Follow these standard procedures to ensure accuracy and quality:

Check all equipment, such as scales and thermometers, for proper function and calibration.

Record every cleaning and sanitation step for compliance and traceability.

Weigh each raw material using calibrated digital scales. Document the exact weight for every ingredient.

Organize ingredients by production phase in separate containers. This prevents mix-ups.

Verify each material’s label, lot number, and expiration date before weighing.

Record all ingredient details, including names, lot numbers, and weights, on standardized batch sheets.

Double-check all measurements before moving to the next stage.

Tip: Careful documentation at this stage helps you track quality and troubleshoot any issues later.

You need reliable equipment to prepare your materials efficiently. Jaywin Machinery offers advanced solutions designed for cosmetic production. For example, their Cosmetic cream equipment features precise mixing and heating systems. These machines help you maintain uniformity and prevent ingredient loss. You can also use specialized filling machines, such as the Gear pump cosmetic liquid foundation cream filling machine, to handle different viscosities and batch sizes.

Jaywin’s equipment supports accurate weighing, mixing, and heating.

Automated controls reduce manual errors and improve repeatability.

Stainless steel construction ensures hygiene and easy cleaning.

You must monitor several critical parameters during material preparation to achieve consistent foundation cream batches:

Maintain correct oil-to-water ratios and use enough emulsifiers to prevent separation.

Use only high-quality raw materials, such as purified water and pharmaceutical-grade white petrolatum.

Ensure water purity by using advanced treatment systems, like two-stage reverse osmosis with electrodeionization.

Check drug concentration and viscosity to match reference standards.

Begin with water treatment to guarantee a clean base for emulsification.

Note: The quality of your raw materials and strict control of preparation parameters directly affect the stability and performance of your final product.

You need the right equipment to prepare the oil and water phases for foundation cream. Advanced machines, like those from Jaywin Machinery, help you achieve uniform mixing and precise temperature control. These features are essential for creating a stable emulsion.

Aspect | Description |

|---|---|

Uniform Mixing | You ensure all materials blend without dead angles, which is important for thick formulations. |

Strong Shear Force | You break down and disperse oil and water phases, making the product smooth and stable. |

Vacuum Environment | You prevent bubbles from forming, which improves the cream’s texture and appearance. |

Efficient Homogenization | You create a fine, nano-level emulsion that absorbs well and feels good on the skin. |

Precise Temperature Control | You keep the mixture at the right temperature, which boosts efficiency and quality. |

GMP Standard Design | You meet industry standards for safety and product quality. |

You should choose equipment that offers these features. This will help you produce foundation cream that meets high standards for texture, stability, and safety.

You must control temperature and mixing speed carefully during oil and water phase preparation. This step affects how well the ingredients combine and how stable your final product will be.

Precise temperature control is essential for emulsifying oil and water phases in cosmetic products.

The recommended temperature for oil and water phase preparation is 70-75°C.

The emulsification process typically requires heating to a range of 70-80°C.

You should heat both the oil and water phases separately to the target temperature. Then, you combine them while mixing at a steady speed. This process helps the emulsifiers work properly and prevents separation. If you keep the temperature and mixing consistent, you will get a smooth, high-quality foundation cream every time.

Tip: Always monitor your equipment’s temperature settings and mixing speed. Small changes can affect the final product’s feel and stability.

You need the right equipment to achieve a smooth, stable emulsion in foundation cream manufacturing. Different types of mixers and emulsifiers help you reach the desired texture and consistency. High shear mixers work well for emulsions with lower viscosity, while multi-shaft mixers handle thicker mixtures. For more complex products, ultra-high shear mixers create fine, stable droplets.

Description | |

|---|---|

Vacuum Homogenizing Emulsifier | Integrates pre-mixing, dissolving, vacuum suction, stirring, heating, homogenizing, and cooling. |

High Shear Mixers | Best for emulsions under 10,000 cP, using strong mechanical and hydraulic shear. |

Multi-Shaft Mixers | Ideal for high-viscosity emulsions over 50,000 cP, combining high shear and laminar flow. |

Ultra-High Shear Mixers | Used for challenging emulsions needing high shear for stability and fine droplet size. |

Jaywin Machinery’s vacuum emulsifiers and mixing tanks stand out in the industry. These machines use a vacuum environment to draw powders into liquids quickly, which reduces processing time and ensures complete ingredient use. The vacuum system also removes air from the tank, preventing oxidation and contamination. This process leads to a smoother, more uniform product and extends shelf life.

Tip: Uniform mixing and air removal are essential for a stable, high-quality foundation cream.

You must control several key parameters during emulsification to produce a stable foundation cream:

Shear Rate: High shear breaks down droplets and reduces their size, which improves emulsion stability.

Emulsification Time: Sufficient mixing time ensures all ingredients combine fully, but over-mixing can damage sensitive components.

Temperature: Keeping the right temperature helps emulsifiers work well and prevents separation.

Temperature changes during production or storage can affect emulsion stability. You should monitor these parameters closely to maintain product quality. The vacuum system in Jaywin Machinery’s equipment also reduces foam and air bubbles, which helps you achieve a smooth, consistent texture every time.

You need the right homogenizer to achieve the perfect texture in your foundation cream. Each type of homogenizer serves a specific function in the manufacturing process. The table below shows the main types you may use and their roles:

Type of Homogenizer | Function |

|---|---|

Produces high-viscosity materials like foundation creams and ensures complete emulsification. | |

Bottom Homogenizer | Delivers high shear mixing at speeds up to 3000 rpm for effective blending. |

Scraper Mixer | Provides even mixing of all materials, preventing buildup on vessel walls. |

Vacuum Device | Removes air through vacuum degassing, maintaining sanitation and preventing contamination. |

Filter | Blocks impurities from entering the main pot during emulsification. |

Perspective Windows with Lighting | Lets you observe the emulsification process without opening the lid. |

Air Exhauster | Extracts air during emulsification to prevent secondary contamination. |

Scratch Mirror Settings | Allows you to monitor the process without fogging obstructing your view. |

You should select equipment that matches your batch size and product requirements. Using advanced homogenizers from Jaywin Machinery helps you maintain consistency and quality in every batch.

You must monitor viscosity and droplet size closely during homogenization. These factors determine the stability and feel of your foundation cream.

Droplet Size and Distribution: Smaller droplets create a more stable emulsion and a smoother texture. A narrow size distribution means your product will look and feel uniform.

Speed and Time: Adjusting mixing speed and time changes droplet size. Higher speeds usually make smaller droplets, but too much speed can cause instability.

Temperature Control: Temperature affects viscosity. Even a 1°C change can shift viscosity by 10% in some fluids. Use temperature-controlled jackets or systems to keep conditions steady.

Visual Inspection: Regularly check the emulsion for separation or uneven droplets. This helps you catch problems early.

Droplet Size Analysis: Use tools like laser diffraction or microscopy to measure droplet size and distribution.

Rotational viscometers help you measure viscosity accurately. You can adjust the speed to match your process needs. By controlling these parameters, you ensure your foundation cream has the right texture, stability, and performance.

After you complete homogenization, you must cool the foundation cream mixture to stabilize its structure and lock in quality. Cooling helps prevent unwanted changes in texture or separation of ingredients. You can use jacketed mixing tanks or dedicated cooling vessels for this step. These machines circulate cold water or glycol around the vessel, which draws heat away from the product. Some systems use rapid air cooling or plate heat exchangers for even faster results.

You should monitor the temperature closely. Most foundation creams need to cool to about 30–35°C before you move to the next stage. This temperature range helps the emulsion set and prepares the cream for filling and packaging. If you cool the product too quickly or too slowly, you may see changes in viscosity or texture. Consistent cooling ensures your foundation cream remains smooth and stable.

Tip: Use temperature sensors and automated controls to keep the cooling process steady and reliable.

You want your foundation cream to look flawless and feel luxurious. Vacuum deaeration plays a key role in achieving this. During mixing and emulsification, tiny air bubbles can get trapped in the cream. When you apply a vacuum, these microscopic bubbles expand and rise to the surface. The vacuum pump then removes them from the mixture. This process leaves your product bubble-free and silky.

Mixing under a controlled vacuum does more than just remove air. It also draws out unwanted volatiles, making your cream denser and more refined. This step enhances the stability of your product and protects sensitive ingredients from oxidation. As a result, your foundation cream not only looks better but also lasts longer on the shelf. You deliver a product with a smooth, appealing texture that meets the highest standards in cosmetics manufacturing.

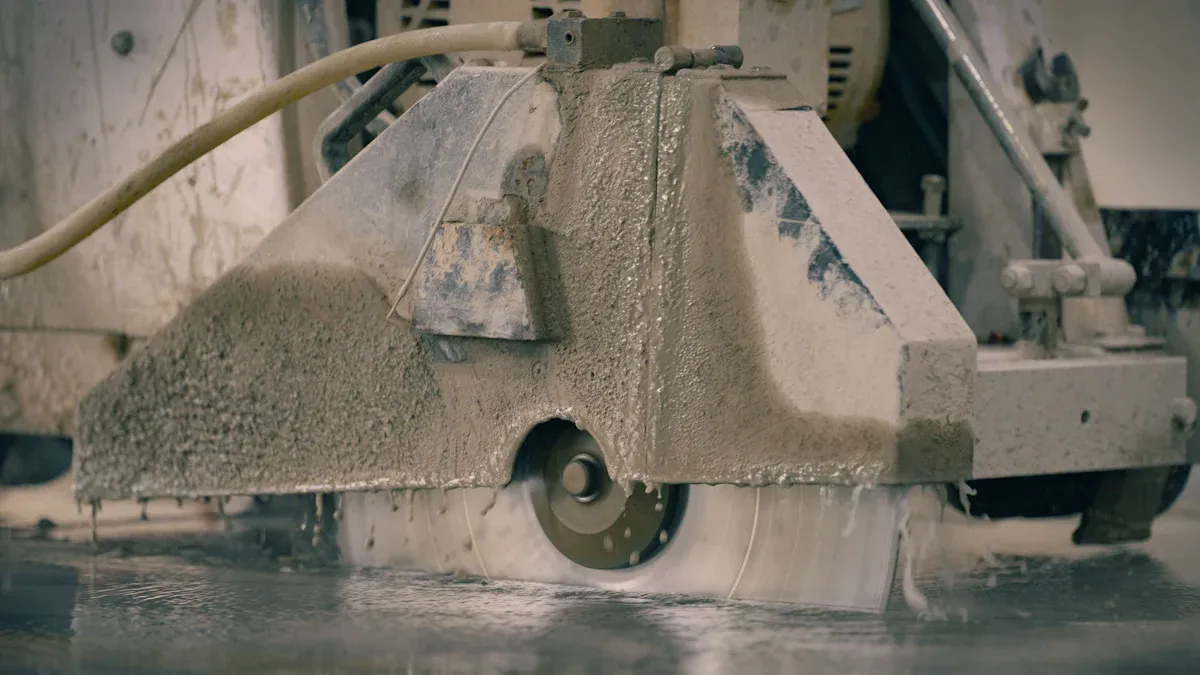

Image Source: pexels

You need reliable filling machines to achieve consistent results in foundation cream manufacturing. Jaywin Machinery offers a range of advanced filling equipment designed for different product viscosities and packaging needs. The Double-head cosmetic foundation cream gear pump heating filling machine stands out for its precision and efficiency. This machine features a double-layer heated bucket, adjustable stirring, and a gear pump system. You can fill both thick and thin creams with accuracy, thanks to its PLC-controlled settings for quantity, time, and temperature.

Jaywin Machinery also provides other specialized filling machines, such as the Gear pump cosmetic liquid foundation cream filling machine and the Four-head Cosmetic paste heating, filling and freezing production line. These machines help you handle a variety of packaging formats, from jars to tubes.

Here is a comparison of the main filling machine types you can use:

Filling Machine Type | Advantages | Suitable For |

|---|---|---|

Precise volumetric dosing, ideal for high-viscosity products | Thick creams and gels | |

Peristaltic Fillers | Gentle handling, high hygiene, suitable for sensitive formulas | Low-viscosity liquids |

You can select the right machine based on your product’s texture and packaging requirements. Each model uses food-grade stainless steel for all contact parts, which ensures hygiene and easy cleaning. The design also supports quick changeovers between batches, reducing downtime and increasing productivity.

Tip: Choose a filling machine that matches your production scale and product type for the best efficiency.

You can boost your production efficiency and maintain high standards by using Jaywin Machinery’s automated packaging solutions. These systems integrate advanced automation features that streamline the entire filling and packaging process. The Double-head gear pump filling machine, for example, offers both automatic and manual operation modes. You can switch between them easily, depending on your batch size and workflow.

The table below highlights key automation features in Jaywin Machinery’s packaging solutions:

Feature | Description |

|---|---|

Automation | Integrates automatic feeding, high-speed grinding, air classification, and cyclone collection |

Material Compliance | Uses food-grade 304 stainless steel, meets GMP standards |

Dust Emission Control | Sealed negative-pressure system eliminates dust emission |

Fineness Adjustment | Achieves nano-level fineness adjustment |

Labor Cost Reduction | Reduces labor costs by up to 40% compared to semi-automatic models |

Intelligent Control | PLC system provides real-time monitoring and automatic alarms |

You benefit from intelligent PLC controls that let you set and monitor parameters in real time. The system can alert you to any issues, which helps you maintain consistent product quality. Automated conveyors and infrared sensors ensure precise positioning of containers, reducing the risk of spills or misalignment.

To maintain hygiene and minimize contamination risks, Jaywin Machinery’s equipment uses several important measures:

Use non-reactive, easy-to-clean stainless steel for all product contact parts.

Schedule regular cleaning of external surfaces and machine frames.

Assign dedicated equipment for allergen-sensitive products to prevent cross-contamination.

Implement drip trays to contain spills and prevent bacterial growth.

Use HEPA filters to keep the production environment sterile.

Employ high-purity water for cleaning to avoid introducing contaminants.

You can trust these systems to deliver safe, high-quality products every time. The automation features not only improve efficiency but also help you comply with industry standards for cleanliness and safety.

Note: Automated filling and packaging solutions from Jaywin Machinery help you reduce labor costs, increase output, and maintain strict hygiene standards in foundation cream manufacturing.

You must monitor key parameters during foundation cream production to ensure every batch meets high standards. pH is one of the most important factors. You should check the pH of your cream to match the skin’s natural level, usually between 5.0 and 7.0. If the pH is too high or too low, the product may irritate the skin or lose stability.

Viscosity tells you how thick or thin your foundation cream is. You can use a rotational viscometer to measure viscosity. If the cream is too thick, it may not spread well. If it is too thin, it may not cover the skin properly. You should check viscosity at different stages to keep the texture consistent.

Microbial load is another critical parameter. You need to test for bacteria, yeast, and mold. High microbial counts can spoil your product and make it unsafe. You should use sterile techniques and test samples regularly. If you find contamination, you must stop production and investigate the cause.

Tip: Regular monitoring helps you catch problems early and maintain product safety.

You need a clear process for sampling, testing, and documenting quality during production. This process helps you track each batch and prove that your products meet safety standards. The table below outlines the standard procedures you should follow:

Step | Procedure Description |

|---|---|

1 | Inspect the storage area for proper organization of materials and handling records. |

2 | Check environmental protection equipment and waste disposal records. |

3 | Review laboratory management systems and testing methods. |

4 | Verify retention sample management and labeling. |

5 | Assess raw material storage conditions and compliance. |

6 | Inspect the production area for cleanliness and proper protocols. |

7 | Ensure equipment maintenance and calibration records are up to date. |

8 | Review batch production orders and sanitation processes. |

You should collect samples at different stages, such as after mixing and before filling. Test these samples for pH, viscosity, and microbial load. Record all results in your batch documentation. Keep retention samples for future reference. This careful documentation helps you trace any issues and prove compliance with industry standards.

Note: Good documentation and regular testing protect your brand and your customers.

You need precise equipment and strict parameter control at every stage of foundation cream manufacturing. This approach ensures:

Consistent viscosity, which affects how your product spreads and how satisfied your customers feel.

Reliable texture, giving your foundation cream smoothness and easy application.

Accurate measurement and monitoring, which drive product innovation and quality.

Jaywin Machinery’s advanced solutions help you overcome common challenges, such as contamination and inconsistent results. The table below shows how you can address key issues:

Stage | Challenge | Solution |

|---|---|---|

Equipment | Use easy-to-clean, hygienic machinery | |

Packaging | Microbial risks during filling | Maintain clean containers and equipment |

Storage | Product degradation | Store in cool, dry, sealed conditions |

Regulatory standards require you to use equipment that supports safe, hygienic production and precise parameter control. When you invest in reliable machinery and focus on quality control, you deliver foundation cream that meets high industry standards and customer expectations.

Prioritize quality at every step. Choose Jaywin Machinery for consistent results and efficient production.

Explore Jaywin Machinery’s products and contact us for tailored solutions.

You need mixers, homogenizers, vacuum emulsifiers, and filling machines. Jaywin Machinery offers specialized equipment for each stage. Choose machines that match your batch size and product type for best results.

You monitor pH, viscosity, and microbial load at every stage. Use calibrated instruments and document all results. Regular sampling and testing help you maintain consistent quality.

Vacuum emulsification removes air bubbles and prevents oxidation. You get a smoother, more stable foundation cream with longer shelf life. This process also improves texture and appearance.

Yes, you can use automated filling machines from Jaywin Machinery. Automation increases efficiency, reduces labor costs, and ensures accurate filling. Intelligent controls help you maintain hygiene and quality.

You clean equipment regularly, use food-grade stainless steel, and follow strict hygiene protocols. Dedicated machines for sensitive products and HEPA filters help you keep the environment sterile.

content is empty!